Leave Your Message

- Phone

- E-mail

- Whatsapp

In the pursuit of optimal system performance, understanding the various "Watercooling Parts" has become crucial for both enthusiasts and professionals in the tech industry. With the rise of high-performance computing and gaming, effective thermal management is paramount; according to a report by Jon Peddie Research, the global gaming hardware market is projected to reach $70 billion by 2025, emphasizing the need for advanced cooling solutions. Properly configured watercooling components not only enhance performance but also extend system longevity, as overheating can significantly degrade hardware lifespan, as evidenced by a study from the Thermal Management Association, which found that excessive heat can reduce component life by up to 50%. Thus, comprehending the function and interconnectivity of each watercooling part is essential for maximizing efficiency and ensuring the reliability of modern computer systems.

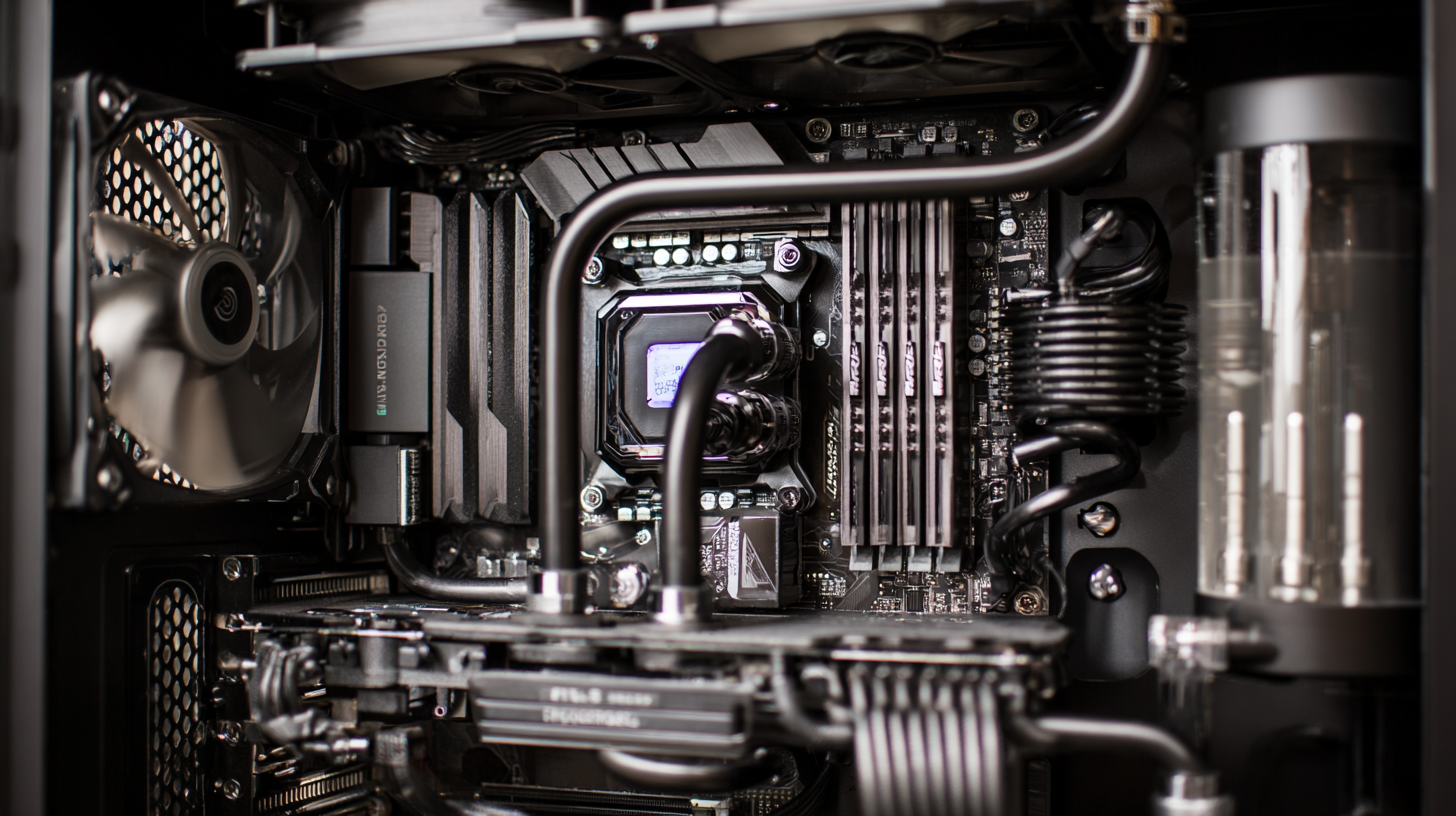

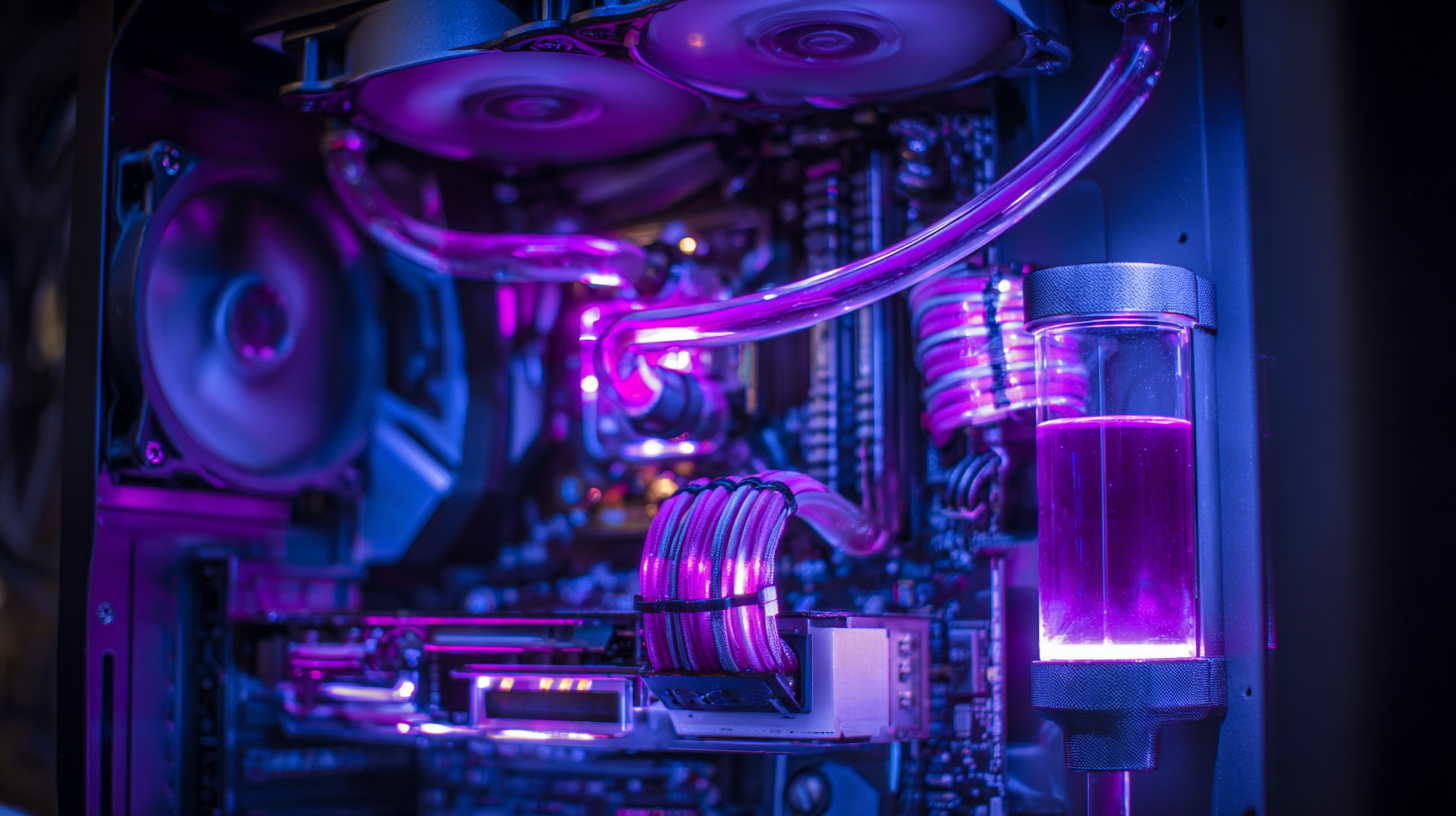

Watercooling systems are essential for maintaining optimal system performance, particularly in high-performance computing environments. Understanding the key components of these systems—the pump, radiator, water block, and reservoir—can significantly impact the effectiveness of heat dissipation. The pump circulates the coolant, ensuring that heat is efficiently transferred from the components to the radiator. This is crucial as a reliable pump guarantees consistent flow rates, which enhances cooling efficiency.

The radiator, often configured with multiple fans, acts to expel the absorbed heat into the surrounding air. Its design and size can affect the cooling capacity, with larger radiators generally providing better thermal management. Meanwhile, the water block, which connects directly to the CPU or GPU, absorbs heat from these components. Its surface area and material influence how effectively it can transfer heat to the coolant, making its design a critical factor in the overall performance of the cooling system. Finally, the reservoir plays a dual role; it not only holds extra coolant but also aids in air removal during setup, ensuring optimal circulation.

Together, these components work synergistically to enhance system stability and longevity, underscoring the importance of understanding their individual roles within a watercooling setup.

The radiator, often configured with multiple fans, acts to expel the absorbed heat into the surrounding air. Its design and size can affect the cooling capacity, with larger radiators generally providing better thermal management. Meanwhile, the water block, which connects directly to the CPU or GPU, absorbs heat from these components. Its surface area and material influence how effectively it can transfer heat to the coolant, making its design a critical factor in the overall performance of the cooling system. Finally, the reservoir plays a dual role; it not only holds extra coolant but also aids in air removal during setup, ensuring optimal circulation.

Together, these components work synergistically to enhance system stability and longevity, underscoring the importance of understanding their individual roles within a watercooling setup.

Understanding radiators is crucial when it comes to optimizing system performance, particularly in watercooling setups. Key factors such as size, material, and efficiency play a vital role in how effectively a radiator dissipates heat. The size of the radiator impacts its surface area and cooling capacity; larger radiators can handle more heat but require adequate space and airflow. Different materials, like aluminum and copper, offer varying levels of thermal conductivity, affecting overall cooling efficiency. Selecting the right combination can significantly enhance system temperature management and longevity.

Understanding radiators is crucial when it comes to optimizing system performance, particularly in watercooling setups. Key factors such as size, material, and efficiency play a vital role in how effectively a radiator dissipates heat. The size of the radiator impacts its surface area and cooling capacity; larger radiators can handle more heat but require adequate space and airflow. Different materials, like aluminum and copper, offer varying levels of thermal conductivity, affecting overall cooling efficiency. Selecting the right combination can significantly enhance system temperature management and longevity.

Tips: When choosing a radiator, consider the specific demands of your cooling system. Ensure that the radiator size fits your case while allowing for proper airflow. Additionally, prioritize materials based on your cooling needs—aluminum is lightweight and resistant to corrosion, whereas copper provides excellent thermal performance. Regular maintenance, including dusting off the fins and ensuring unobstructed airflow, also contributes significantly to radiator efficiency.

When it comes to water cooling systems, the pump is one of the most critical components that directly affects cooling performance. The pump's primary function is to circulate coolant throughout the system, ensuring that heat extracted from the CPU and GPU is efficiently transferred to the radiator for dissipation.

A reliable and powerful pump can significantly improve flow rates, which enhances the overall cooling efficiency. Therefore, selecting the right pump based on your system's needs is essential for optimal performance.

Tips: When choosing a pump, consider the flow rate specifications provided by the manufacturer. An ideal pump should strike a balance between power consumption and performance. Additionally, it's important to assess the total length and complexity of your loop, as longer circuits may require more robust pumps to maintain adequate flow rates.

In addition to pump selection, understanding compatibility with other components is crucial. Ensure that the pump's inlet and outlet sizes match the diameter of your tubing, as mismatches can lead to flow restrictions.

Opt for a pump that offers adjustable speed settings, allowing you to fine-tune the flow rate based on your cooling needs, which is especially beneficial during intensive usage periods.

In the realm of water cooling, the water block plays a crucial role in ensuring optimal system performance. The effectiveness of heat transfer from the CPU or GPU to the coolant largely depends on the material and design of the water block. Copper and aluminum are the two most common materials used in manufacturing water blocks. Copper, with its superior thermal conductivity, facilitates rapid heat transfer, making it the preferred choice for high-performance systems. In contrast, aluminum is lighter and more cost-effective but often sacrifices some efficiency in heat dissipation.

The design of the water block also significantly impacts heat transfer performance. Features such as microchannels, which increase surface area, enable more efficient coolant flow across the heat source. Additionally, factors like the thickness of the base plate and the shape of the water block can influence how effectively heat is absorbed and transferred to the coolant. A well-designed water block not only enhances thermal efficiency but also contributes to maintaining system stability and longevity, underscoring the importance of selecting the right components in a water cooling setup.

| Material | Thermal Conductivity (W/m·K) | Design Type | Weight (g) | Typical Use Case |

|---|---|---|---|---|

| Copper | 390 | Standard | 300 | High-performance CPUs |

| Aluminum | 205 | Budget | 450 | Mid-range systems |

| Nickel-Plated Copper | 350 | Premium | 320 | High-end gaming rigs |

| Acetal / POM | N/A | Plastic | 200 | Custom water loops |

| Graphene | 5000 | Innovative | 250 | Next-gen cooling systems |

When setting up a watercooling system, selecting the right tubing and fittings is crucial for ensuring optimal performance and reliability. Tubing serves as the medium through which coolant flows, and its material and diameter significantly affect the flow rate and overall cooling efficiency. Common materials include PVC, silicone, and rubber, each presenting different advantages concerning flexibility, durability, and temperature resistance. A wider diameter can reduce flow resistance, but it's essential to balance this with compatibility with the pump and block sizes.

Fittings, on the other hand, are the connectors that secure the tubing to various components, and they need to be both leak-proof and easy to install. Choosing high-quality fittings made from materials like brass or stainless steel can prevent corrosion and leaks over time. It's advisable to match the fittings to the tubing size accurately to avoid any flow issues. Additionally, opting for swivel fittings can ease installation, especially in tight spaces, allowing for better maneuverability. By understanding the intricacies of tubing and fittings, enthusiasts can build a more efficient and reliable watercooling setup.